Monitor with Confidence

Welcome to SpotSee

SpotSee monitors and indicators are designed to spot changes in environmental condition, so you can identify damage throughout the supply chain. Even the smallest changes in temperature, shock, tilt, location, humidity, and light sensitivity can make a big difference in shipping valuable products. By tracking these small details, we help our customers ensure that whatever is being transported – from life-saving medicine and therapeutics to sensitive cargo – arrives safely and in the best possible condition.

SpotSee’s products are widely used in various industries, including pharmaceuticals, diagnostics food and beverage, electronics, manufacturing, and logistics. Use SpotSee and deliver with confidence.

Industries We Serve

Life Science

Aerospace

Aerospace components, built for safe flight, are vulnerable during transport. SpotSee solutions help reduce they face damage from unexpected impacts.

Automotive

Supply Chain

Solutions

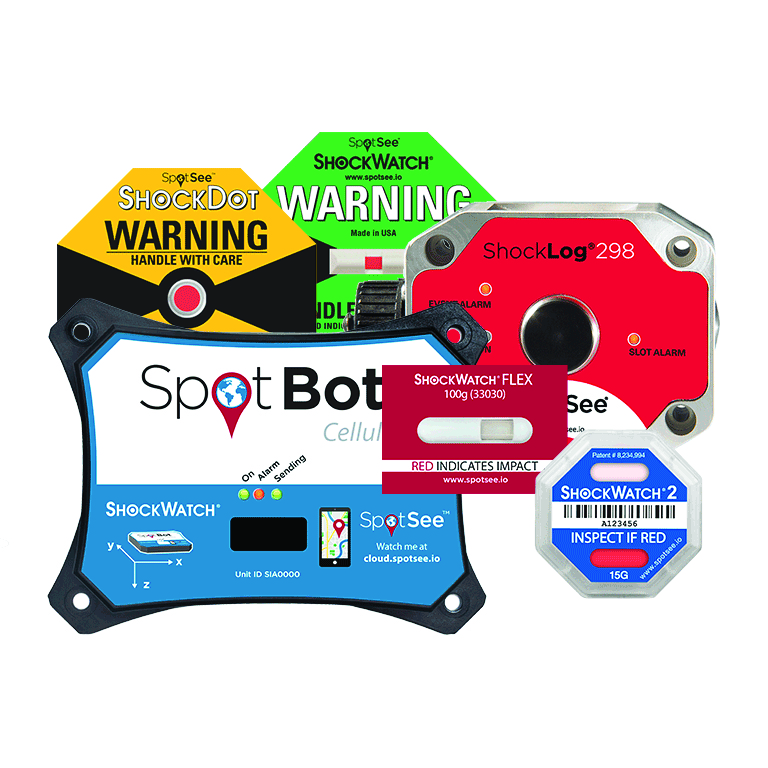

FEATURED PRODUCTS

WarmMark

MaxiLog Alert -80°C

The best-in-class data logger for extreme cold transport, the Maxilog Alert combines robust temperature monitoring with simple data retrieval via built-in USB interface with direct download to software.

ShockLog

The ShockLog devices monitors and records impact and environmental conditions experienced by sensitive equipment, whether in use, transit, or storage – detecting seismic-level g-force. The device alerts you when damage may have occurred, so you can respond promptly.

ColdChain Complete

Product Categories

Latest Blogs

News

FreezeSafe: Low-Cost Simple Indicator for Life Science Application

Safeguarding Pharmaceutical Integrity: How FreezeSafe from SpotSee Ensures Vital Temperature Control In the world of pharmaceuticals, maintaining temperature control is paramount to preserving the efficacy and safety of various products. Certain pharmaceuticals, such...

Thermax® Condition Indicators Help Rail Car Owners Prevent Bearing and Other Overheating Problems

Cold chain logistics is the larger system and equipment used to safely transport goods that are temperature sensitive. Think of the cold supply chain as consistent and uninterrupted temperature control throughout the entire supply chain network.

Cold Chain Temperature Indicators to Support Safe Pharmaceutical Delivery

Cold chain logistics is the larger system and equipment used to safely transport goods that are temperature sensitive. Think of the cold supply chain as consistent and uninterrupted temperature control throughout the entire supply chain network.